General Purpose Blades

Our General Purpose blades are specifically engineered for use with a wide variety of general purpose cutting conditions while constructing your hardscape projects.

Features

Applications

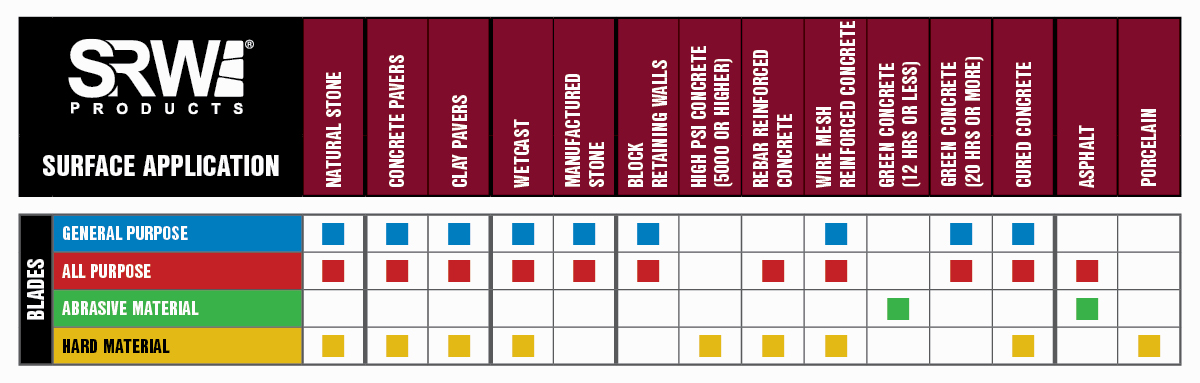

Application Chart

Product Details

Features

- Standard and premium options available

- Specifically engineered to meet the challenges of all general-purpose cutting conditions

Applications

- Brick/Clay

- Cured Concrete

- Sandstone

- Limestone

- Travertine

- Retaining Wall Block

- Concrete Block

- Reinforced Concrete w/Wire Mesh

Application Chart

Product Details

General Purpose Diamond Blades (Blue)

| PART NUMBER | SIZE | THICKNESS/ SEG HEIGHT | ARBOR | STYLE | SLOT STYLE | COOLING HOLES | GRADE |

| BTP 4 | 4″ | .250″ / 10 mm | 7/8˝-5/8˝ | Seg | Key-Hole | No | Standard |

| BU 04.5 | 4.5″ | .080˝/8 mm | 7/8˝-5/8˝ | Continuous Turbo Rim | None | Yes | Standard |

| BU 045 SEG | 4.5″ | .030″/8 mm | 7/8″-5/8″ | Seg | Key-Hole | No | Standard |

| BU 07 | 7″ | .095˝/10 mm | Universal | Continuous Turbo Rim | None | Yes | Standard |

| BU 07 SEG | 7″ | .095˝/10 mm | Universal | Seg | Key-Hole | No | Standard |

| BU 09 | 9″ | .090″/10mm | 5/8˝ – 7/8″ | Turbo Seg | Key-Hole | No | Standard |

| BGPC 09 | 9″ | .090″/10mm | 5/8˝ – 7/8″ | Seg | Key-Hole | No | Premium |

| BU 10 | 10″ | .095˝/10 mm | Universal | Seg | Key-Hole | No | Standard |

| BGPC 10 | 10″ | .095˝/10 mm | 7/8˝-5/8˝ | Seg | Key-Hole | No | Premium |

| BU 12 | 12″ | .125˝/10 mm | 1˝/20 mm | Seg | Key-Hole | No | Standard |

| BGPC 12 | 12″ | .125˝/12 mm | 1˝/20 mm | Seg | Key-Hole | No | Premium |

| BU 14 | 14″ | .125˝/10 mm | 1˝/20 mm | Seg | Key-Hole | No | Standard |

| BGPC 14 | 14″ | .125˝/12 mm | 1˝/20 mm | Seg | Wide Key-Hole | No | Premium |

| BGPZ 14 | 14″ | .125˝/15 mm | 1˝/20 mm | Alt Turbo Seg | Key-Hole | Yes | Premium |

| BGPX 14 | 14″ | .125″/15 mm | 1″/20 mm | Turbo/Crown | Narrow U-Slot | Yes | Premium |

| BGPQ 165 | 16.5″ | .125″/12 mm | – | Alt Turbo Seg | Narrow U-Slot | no | Premium |

Contractors & Homeowners

Visit our Dealer Locator to find out where you can purchase our products!

X-Treme Diamond Blade: A New Segmented Design

Customers Also Search

Related products

Frequently Asked Questions

Where can I buy SRW diamond blades?

Call us at 1-800-752-9326 or use our dealer locator. We will gladly help locate a dealer near you!

Can I cut asphalt with a general purpose blade?

The General Purpose blades can cut a small amount of asphalt but will wear quickly because of how abrasive asphalt is. SRW recommends using a blade that is specific for cutting asphalt such as the Abrasive Material blade.

Why does the blade seem to be wobbling when cutting?

Two causes are possible. First, check your bearings, they should not be loose or worn. Also, make sure the blade is not loose. Second, if the blade has overheated it may lose tension and start to wobble.

Do you have additional questions? Contact us.

Download Our Catalog

Frequently Asked Questions

Where can I buy this product?

Call us at 1-800-752-9326 or use our dealer locator. We will gladly help locate a dealer near you!

Do you have additional questions? Contact us.

Download Our Catalog